How Las Vegas Glass Is Made: Behind the Scenes of a Modern Craft

Glass surrounds us in everyday life—from panoramic doors and resort windows to the neon glow of the Strip. But how exactly is Las Vegas glass made, and what sets it apart in a city where design and durability matter?

In the 15-minute video below, we walk through the entire process, step by step. Here’s a written overview to guide you through what you’ll see.

Step 1: Raw Materials

Glass begins with a simple but carefully measured recipe:

-

Silica sand (the main ingredient, making up 60–70%)

-

Soda ash (lowers the melting point)

-

Limestone (adds strength and stability)

-

Trace minerals and recycled glass (known as cullet)

Las Vegas manufacturers often use high-quality desert sand, refined to remove impurities. The addition of cullet not only speeds up melting but also reduces energy consumption—important in a region focused on efficiency.

Step 2: Melting and Refining

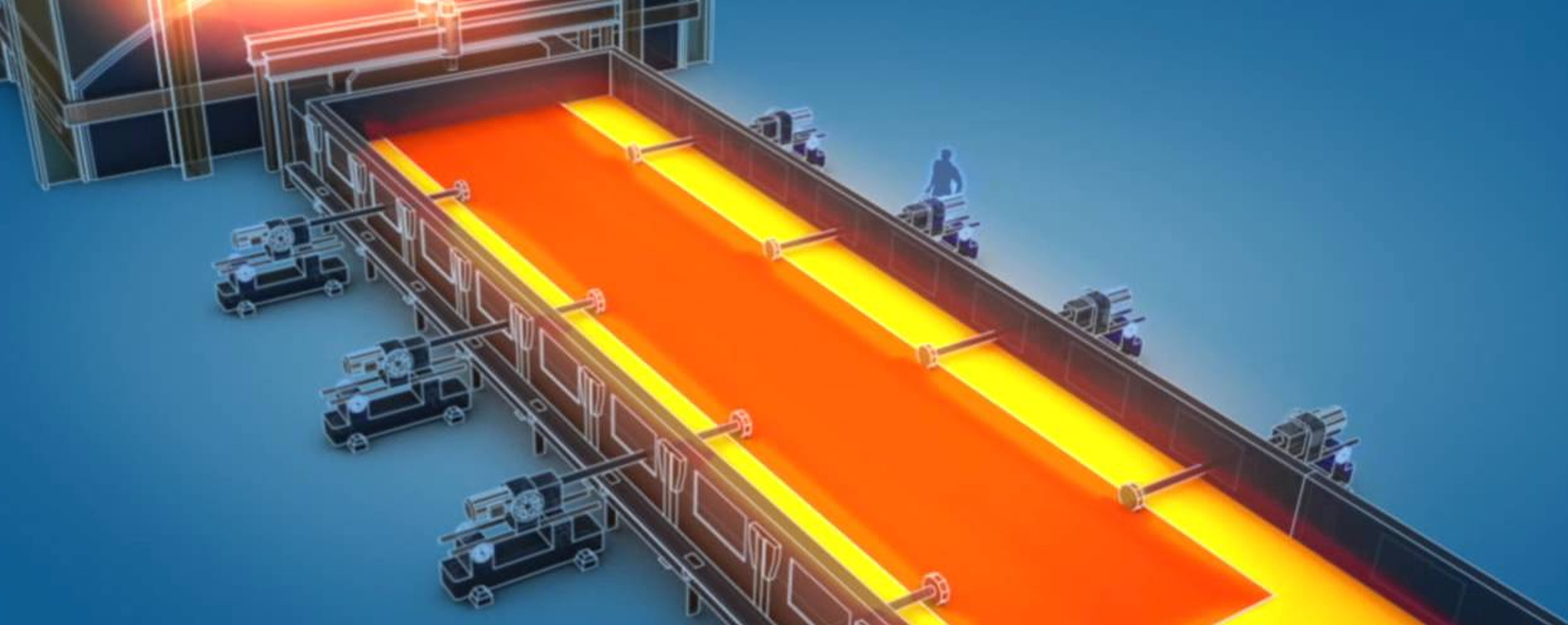

The mixture is fed into a furnace heated to over 2,600°F. At these extreme temperatures, the sand and minerals liquefy into molten glass. Any bubbles or inconsistencies are smoothed out in this refining stage to ensure clarity.

Step 3: Forming the Glass

Most modern flat glass in Las Vegas is made using the float glass process. The molten glass is poured onto a bath of molten tin, where it spreads out evenly and forms a perfectly smooth surface. As it cools, it begins to harden into long, continuous sheets.

From here, glass can be:

-

Cut into panels for windows and doors

-

Rolled or pressed for decorative textures

-

Molded into specialty shapes

Step 4: Cooling and Annealing

The glass sheets pass through an annealing lehr, a controlled cooling tunnel. This stage relieves internal stresses and ensures the glass won’t crack or shatter under everyday conditions.

Step 5: Strengthening and Finishing

Depending on the final use, glass may go through extra treatments:

-

Tempering (rapid heating and cooling for strength—often 4x stronger than standard glass)

-

Laminating (bonding layers for safety glass)

-

Coating (adding reflective or low-E finishes to manage Las Vegas heat and sun exposure)

These enhancements make glass suitable for everything from high-rise hotels to panoramic luxury doors.

Why Las Vegas Glass Is Unique

In a city that blends extreme desert conditions with world-class design, glass must meet higher standards. Homes and resorts demand:

-

Energy efficiency to reduce cooling costs

-

Durability to withstand high UV exposure

-

Clarity and aesthetics to complement modern architecture

That’s why the process isn’t just about making glass—it’s about making glass that thrives in the Mojave.